The Internet of Things (IoT) is a hot topic in the press today that is stealing many headlines. The reason for all this attention comes from the rapid growth expected in the IoT world. According to Berg Insight, the number of wireless IoT devices in automation networks is now forecast to grow at a compound annual growth rate (CAGR) of 27.2% to reach 43.5 million by 2020. However, the Industrial Internet of Things (IIoT) is more of a near-term reality, and many industrial firms are striving to take advantage of its benefits. There are many different terms for IIoT, including Industry 4.0. and the Connected Factory. Whatever you choose to call it, how can you take steps to get in the game with IIoT?

The Challenge – IIoT Readiness

One might wonder how to get started with IIoT, especially when you look out at your organization and see equipment from different manufacturers that is five, 10, or 20 years old or more. How can you solve the challenges of being IIoT ready when you use legacy devices to operate many of your processes?

Replacing equipment is not an option because of cost and integration time. You need to find a way to not only protect your existing investment, but also make it compatible with more modern equipment. This may seem to some like a best-of-both-worlds scenario.

The Answer – Protocol Conversion

Protocol conversion is a key first step in solving the multi-vendor and legacy equipment challenge. Wikipedia describes a protocol converter as "a device used to convert a standard or proprietary protocol of one device to the protocol suitable for the other device or tools to achieve the interoperability."

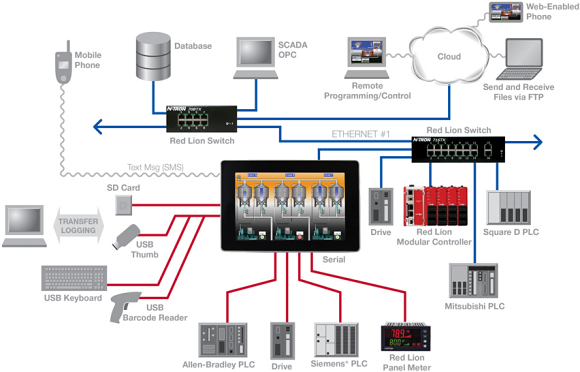

There can be many different devices on a manufacturing floor, with each one having its own protocol, so organizations can have a situation where you need to handle several different protocols in order to gather data. The ability to provide protocol conversion in a Human Machine Interface (HMI) or other automation products across a multi-vendor environment is a great way to connect several different devices with different protocols and be able to aggregate that data collection.

Protocol conversion allows you to collect data from different devices and different protocols and translate those in a centralized device so that you can collect and compile data from all over the factory floor. Then, you can turn this information and data into useable, trend-related information and reports that help you to make informed decisions and do effective planning of your resources. Some refer to this as the mining and displaying of data for actionable intelligence, which gives you real-time visibility to help make operations more efficient.

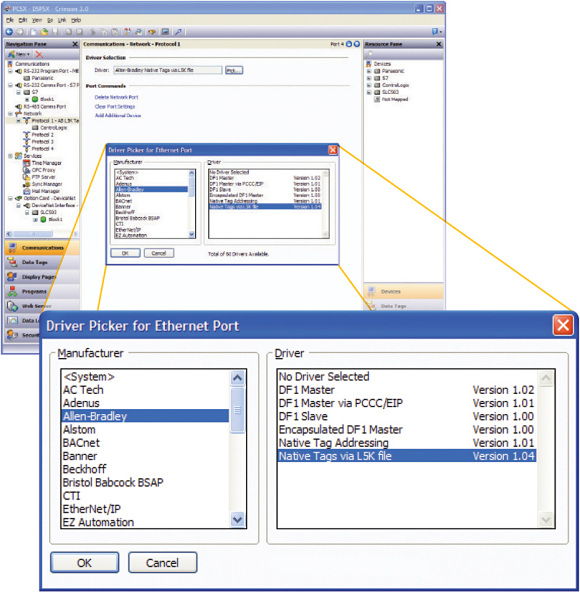

Fig. 1: A sample screenshot from Crimson protocol-conversion software.

Connect – Speaking the Same Language

You can benefit from bringing new and legacy equipment together on the same network. Some of the newer equipment on the factory floor may be Ethernet ready while older equipment may use a serial connection and a legacy protocol specific to that vendor. By integrating different devices and getting legacy devices talking with newer devices, you can get disparate equipment to communicate across multi-vendor environments.

Industrial environments are embracing newer communication infrastructures such as cellular M2M, Wi-Fi, Gigabit Ethernet, fiber, and Power over Ethernet. These communication technologies help deliver and enable higher-bandwidth applications that bring more information and intelligence to manufacturing environments.

Fig. 2: Diagram of a network employing a variety on current and legacy devices and interfaces.

Monitor – Using Data to Visualize Processes

Protocol conversion is also important for monitoring processes, i.e., collecting and analyzing data to develop more efficient operations and reduce downtime. In particular, when protocol conversion is implemented in multi-vendor environments, users can leverage visual management solutions to display key performance indicators (KPIs) that can be used for tracking, assessing and analyzing manufacturing processes.

These performance measurements are commonly used to evaluate success in relation to goals and objectives. While KPIs tend to vary by organization, common examples of KPIs in manufacturing include count (good or bad), reject ratio, rate, target, Takt time, Overall Equipment Effectiveness (OEE), and downtime.

Control – Increasing Operational Efficiencies

Protocol conversion can help you integrate PLCs, PCs, and SCADA systems to collect and process data in real-time to control devices and applications that directly affect operations. Exercising control over operations could mean such things as having the ability to turn legacy serial-connected equipment on or off, or open or close valves regardless of location.

In conclusion, addressing IIoT challenges through protocol conversion enables organizations to improve productivity and increase operational efficiencies through real-time device connection and data processing. With protocol conversion, you can get all of your devices, both legacy and new, communicating to provide a holistic environment view that allows you to plan more effectively and take action. By enabling disparate devices to communicate, you can now connect, monitor, and control operations from a single platform. This type of data-driven monitoring and decision-making will get you on your way to IIoT readiness.

About the Author

With nearly 40 years experience in industrial automation, Jeff Thornton has held product, sales and technical positions at Red Lion Controls. In his current role as Director of Product Management, Jeff is responsible for strategy and development of the company's Human Machine Interface (HMI), panel meter, PID controller and protocol converter product lines.

Related Stories

Capturing the Business Value of the Industrial IoT

NI Launches Next-Generation Control Systems Optimized for the Industrial Internet of Things

Industrial IoT Market Worth $319.62 Billion by 2020

Red Lion Adds New Event Engine to RAM Industrial Cellular RTUs