Even before terrorism cast a long shadow over international and interstate commerce, customs inspectors naturally wanted to know what was in sealed transport vessels coming across our borders and how much of it each container held. Today, the practice of manually opening drums and tankers at random and investigating their contents with a flashlight and stick, time-consuming and tedious under the best of circumstances, has become too dangerous for all but the most demonstrably benign of cargoes. So researchers at the Department of Energy?s Pacific Northwest National Laboratory (PNNL) have developed an inspection technology that?s faster, safer, and more accurate.

|

The Acoustic Inspection Device, or AID, is a handheld instrument (see Figure 1) that measures the acoustic velocity and attenuation of ultrasonic wave pulses as a way to analyze the liquid contents of sealed containers and verify that they match the manifest. Half-empty drums, hidden compartments, or objects such as firearms immersed in the containers? contents register as anomalies, as do liquids that are not precisely what they claim to be. The technique is accurate enough to distinguish between regular and diet cola, and can recognize a particular weight of motor oil at the Canadian border in January or the Mexican border in July.

AID Components

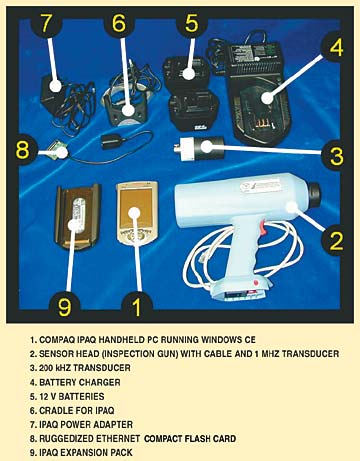

The 4 lb. AID (see Figure 2) is powered by two rechargeable 12 V, 10 hr. batteries and operates at frequencies from 1.5 MHz to 140 kHz, enabling it to accurately identify a wide range of substances.

Figure 2. In addition to the piezoelectric PZT transducer, the AID has an integral thermistor to compensate for ambient temperature and a database of known substances against which a new sample can be compared. |

It has two interchangeable transducers, 1 MHz for containers as small as a 2 L bottle and 200 kHz for larger-sized ones such as railroad and highway tankers. An onboard database contains a library of temperature-specific acoustic datasets for each substance to be identified (see Figure 3) and an integral thermistor to compensate for ambient temperature.

Figure 3. Every substance has a unique acoustic velocity and attenuation; these properties are functions of temperature. |

The database can be easily updated, and internet connectivity enables exchanges with other inspection sites so that customs officials can track and share information for ports across the country.

Operation

After measuring the container?s diameter and entering it in the onboard PC, the inspector holds the AID against the side of the vessel and squeezes the trigger to launch an ultrasonic pulse. A gel-filled coupling, also developed at the lab, fits over the transducer nozzle to ensure an airtight contact with the container. By taking several measurements, working from the bottom of a container up, inspectors can determine a container?s fill level.

When the AID is activated, a waveform display (see Figure 4) appears and then disappears as the trigger is released.

Figure 4. When the AID?s trigger is squeezed, a waveform display shows the signal acquired from a tanker truck (green). The threshold lines are yellow and the transit time envelope on the lower portion of the graph is green. |

|

The AID may be set for material ID, contraband inspection, or comparison mode. ID mode looks for a specific substance; comparison mode compares an initial reading with subsequent measurements and can be used to ensure that all containers in a shipment have the same contents. Contraband inspection mode allows the operator a rapid means for identifying hidden compartments, floating objects, or other anomalous conditions.

Principles

Velocity. The speed of sound in a liquid, VL, is a function of both density and compressibility and is accurately determined by means of a cross-correlation algorithm:

| then |

(1) |

where:

| ß | = | compressibility |

| then |

(2) |

where:

| d | = | container diameter |

|

|

= | time differential between two successive echoes |

Attenuation. Attenuation is the other measurement parameter used by the AID. While acoustic velocity varies by less than a factor of two over a wide range of fluids, attenuation can vary by several orders of magnitude but is also much more difficult to measure accurately. Attenuation is measured on a scale normalized to 1?6; 1, water, is the least attenuative and 6 is the most. The AID algorithms perform spectral analyses of nonsaturated multiple echoes in the acoustic time series. By using multiple echoes in the substance under test, variations due to coupling, geometry, container wall material, and other factors are negated and the need for reference spectra is eliminated. The attenuation data can prove very reliable in distinguishing among substances when the operator is able to acquire multiple, nonsaturated echoes.

The AID compares the frequency content of two consecutive echoes over the known path length. The algorithm determines the ratios of amplitudes at various frequencies and uses a multistep computational process to compute the attenuation coefficient.

Velocity Attenuation Measurement System

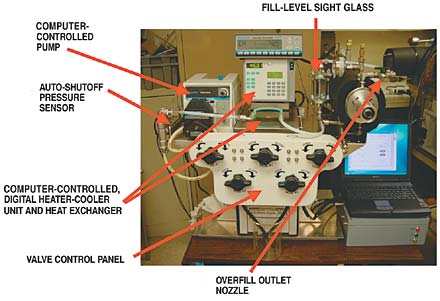

In 2002 PNNL developed the Velocity Attenuation Measurement System (VAMS) to automate the process of building data sets of velocity and attenuation data for various substances over a range of temperatures. VAMS (see Figure 6) allows a researcher to specify the temperature range (typically 40°F?120°F) and temperature increments (typically 5°?10°).

Figure 6. Pacific Northwest National Laboratory developed the Velocity Attenuation Measurement System (VAMS) to automate the process of building data sets for substance identification over a range of temperatures. |

The system can usually characterize a 2 gal. sample in ~6 hr.

The liquid of interest is put into the interchangeable liquid containment vessel and tested across the temperature range with a transducer probe operating at 1 MHz and 52 dB of amplifier gain range. The entire system fits on a laboratory benchtop and operates on a standard 115 V power supply. The AID computer is mounted on the VAMS laptop control platform for data downloads.

PNNL also developed an algorithm that uses digitized waveforms of the ultrasonic return signal, temperature readings, and path length measurements in the VAMS to calculate temperature-corrected ultrasonic velocity and relative attenuation coefficient values. These values are automatically ported to a database, and a comprehensive file for the liquid is generated and ready for downloading at the end of the characterization process. The system can analyze liquids of almost any conceivable chemical composition and determine echo velocity and attenuation measurements over a wide range of temperatures. Researchers can thus create customized databases, populate them rapidly, and distribute them to clients via the Internet.

The research was sponsored by the U.S. Department of Energy, the U.S. Bureau of Customs and Border Protection, and other government agencies, and conducted by Pacific Northwest National Laboratory, which is operated by Battelle for the U.S. DOE.

PNNL has licensed the technology to Mehl, Griffin and Bartek Ltd. of Arlington, VA, which has teamed with International Engineering & Manufacturing of Media, PA, to begin production of the system for U.S. Customs. The AID is now commercially available under the name Product Acoustic Signature System, or PASS.