GKN Wheels—one of the world's leading manufacturers of wheels for any kind of light or heavy agricultural, construction, and off-highway machinery—approached Sigmapi Systems Ltd. with a challenge. The company uses a range of materials in the construction of wheels and was experiencing high levels of bad welds. What the company wanted was the ability to monitor several properties of the butt-weld process to improve the success rate. Because of the large variation in the age and type of equipment the machine must be very versatile.

The Specifics

The parameters that need monitoring include current usage (up to 3000 A to an accuracy of 1%), voltage (up to 14 V to an accuracy of just a few mV), pressure (up to 2200 psi to an accuracy of 1%) and displacement (0–50 mm with an accuracy of 1%). The data had to be collected at 1000 sps/channel during the weld process and stored for later analysis and comparison.

The data logging equipment would have to withstand the incredibly electrically noisy environment of industrial welding and, for health and safety reasons, the operator could get no closer than 4 m to the welding station to run the tests.

Finally, the equipment had to be portable so that it could be moved from site to site anywhere in the world, which also meant that it had to be capable of monitoring different types of butt welds (for example, some are AC powered, others use DC).

The Solution

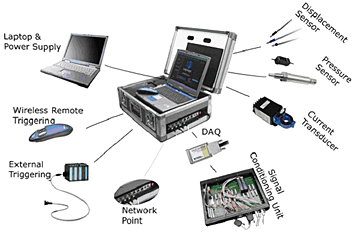

Sigmapi Systems decided the best way to solve this challenging problem was to enclose the data logging system in a portable, purpose-built carrying case that would also serve as the data capture and analysis unit, with compartments to hold all the sensors and cables when the unit was being transported to different sites (Figure 1). In other words, this is a handy self-contained system.

Figure 1. An exploded view of the DA system |

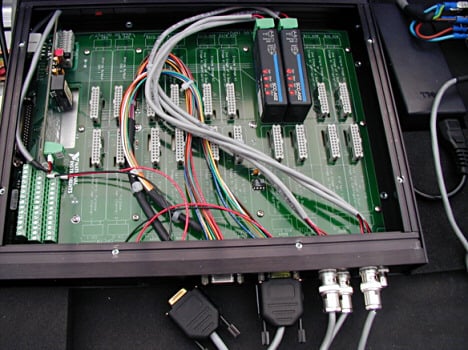

For the signal condition and DA, we decided to use a National Instruments SCC unit that provides portable, modular signal conditioning. This combines a low-profile carrier unit and a wide range of modules that plug into the carrier to provide the specific signal conditioning needs (Figure 2). This also allows us to add extra sensors (by adding extra SCC modules) if the customer wished to monitor other properties of the weld process. To calibrate and set up the system we used National Instruments' Measurements & Automation Explorer (MAX) software GUI.

Figure 2. A close-up of the signal conditioning unit |

For DA, we chose a PCMCIA DA card in a laptop, ideal for applications with high-voltage signal or sensor measurements, and allowing a sampling rate to 1 Ksps at 16-bit resolution for up to 16 analog channels.

Because of the need to maintain a standoff distance from the welding station for operator safety, we chose to trigger the test's start with a digital input from a remote triggering device (which could be either wired or wireless to give the customer maximum flexibility). An LED on the case would inform the operator when a test was running to provide feedback.

The software for test setup and data logging was written in LabVIEW because this provides all the necessary drivers for the hardware used, making the system much quicker to develop. The software system was designed and written to allow the operator to set up tests, remotely trigger a test, log the data to spreadsheet files, and launch the files in Excel for analysis.

The Result

The unit was delivered to GKN and, following tests at their U.K. site, it was then taken to their Denmark, Italy, and U.S. sites. The unit was used on a variety of butt-welding equipment (including AC flash butt and DC butt welding) and was capable of measuring the key parameters on both CAM-operated and hydraulic servo machines.

We were told that the unit had paid for itself three times over in the first month of use. Its high capture rates enabled engineers at GKN to diagnose equipment faults prior to complete failure and to detect weld procedure faults not visible to the naked eye, highlighting problems with welding stations.

In the original conception, the unit was to be used by (and travel among) the four GKN Wheels sites. However, the unit proved so successful that each plant decided to purchase its own unit, resulting in orders for three more units for its U.K., Denmark, and Italy sites.

Building on lessons learned with the first unit, the Mark II unit incorporated the ability to measure each weld automatically, allowing direct comparison of each weld in Excel. This enables the definition of working parameters for each machine range from which good welds can be expected.

The original Mark I unit has been to four different countries on numerous visits; it traveled in the holds of airplanes and had been in almost constant use before its adoption by the U.S. plant, who returned it to us (travel-worn and covered in travel stickers) for a complete refurbishment and upgrade to Mark II.