Bioprocess development and production engineers have identified an increasing and largely unmet need for improved real-time, in situ measurement of key components in fermentations, for example the concentration of key nutrients and product, so that process feeding regimes can be optimized and automated. The need for these measurements is driven by several factors: the reduction of production costs, faster process development, and improved process robustness and product quality. Major initiatives from the regulatory authorities such as Quality by Design (QbD) and Process Analytical Techniques (PAT) encourage the biopharmaceutical industry to address these needs. The requirement is to measure fermentation components through all stages from process development through to pilot plant and full-scale manufacturing.

Bioprocessing is used to produce a wide range of products, such as food, biofuel, and pharmaceuticals. A simple form of bioprocessing is beer production, a yeast fermentation process where malted barley is used as a food source or feedstock for yeast, which is a live culture or living organism. The yeast converts the sugars within the barley to alcohol. While other bioprocesses may be much more complex, they all involve a food source and an active agent (e.g., yeast) and output a product. The task of the process development team is to optimize the process so that the product yield is maximized and the costs are reduced. An important factor in delivering an optimized process is to control the addition (dosing) of the feedstock so that the active agent operates at a high metabolic rate. Too little feedstock and the agent may die; too much and the agent may overdose. The ability to monitor and control the health of the bioprocess media is of primary interest to process development engineers.

This article describes an innovative micro-optical sensor based on solid-state silicon and fiber-optic technology that sits within the process reactor vessel, for either laboratory or production scale processes. Stratophase manufactures optical structures that route light (delivered via fiber-optic cable) around a small silicon chip and into the process media. The light signal responds to compositional and metabolic rate changes within the reactor vessel in real-time, shifting the wavelength of the returned signal in response to changes in the chemical composition of the process media. Depending on the generic process type, this wavelength shift can act as a characteristic signature. For example, the sensor will "see" media changes in yeast and mammalian processes that are unique to each process but that are dominated by changes in the glucose and protein concentration, respectively. The rate of change of the signature indicates the metabolic rate of the active agent. The system derives the agent's maximum metabolic rate, which can then be used to trigger the next feedstock addition and thus maintain the optimal metabolic rate to maximize product yield.

The Stratophase products, comprising an industry-standard probe (the Ranger Probe) and its control system (the Ranger Manager) can be used in the control and monitoring of all stages of biotechnology processes from upstream where, for example, component concentrations are adjusted prior to use in the bioreactor production vessel, to fill-and-finish where, for example, dosage concentrations of a drug are controlled prior to packaging the drug in its delivery format. The Ranger system's technology provides real-time insight into nutrient consumption and product expression (the desired chemical produced by a bioprocess, e.g., the protein generated from a mammalian biopharmaceutical process or alcohol from a yeast fermentation), thus generating the crucial information needed to enable real-time control of the process.

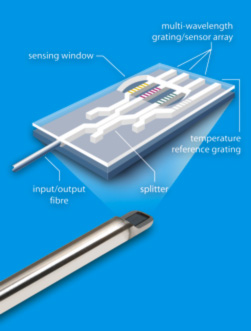

Figure 1. A diagram of the silicon chip at the heart of the Ranger Probe |

The Ranger System can be integrated into all bioprocesses that use microbial and mammalian cell cultures. It enables bioprocess managers to monitor the cells' metabolic rate, observe both single- and batch-to-batch trends, and accurately determine the end of the process. End of process is the point at which the active agent has either exhausted its food source or has been poisoned by the product. In our beer example, end of process occurs when the yeast has consumed all the available sugars from the barley or has been poisoned by the alcohol. This end point can be difficult to determine using existing techniques, which do not monitor the media's metabolic condition. Stopping the process too early or too late directly affects the volume of product produced in a given period, reducing name-plate capacity. The name-plate capacity refers to the intended full-load, sustained output of a facility and is an important production metric. The output from Ranger is used to automate and optimize the feeding regime of the media. We will use the Ranger in a microbial fed-batch control process where feedstock is added throughout the process run to illustrate its use.

Technology

The optical structures at the heart of the Ranger Probe route light around a small silicon chip (Figure 1). By immersing the sensor in the process media, the probe can directly measure the refractive index of the media by sensing the shift in wavelength between the incident light and the light returning from the media. This real-time measurement responds to the rate at which the active agent converts the feedstock into product (metabolic rate), any nutrient additions, and the end of the process.

The Ranger System (Figure 2) consists of two components: the Ranger Manager, which controls the sensor and the Ranger Probe real-time sensor, which sits within the process media. Communication between the two devices is by noise-immune fiber-optic cable. The Manager contains a laser light source, detectors that are Bragg gratings embedded within the silicon, data reduction components, communication modules, and user interface components. The system features standard outputs such as OPC and 4–20 mA to enable communication to process-control systems.

Figure 2. A diagram of the Ranger System |

Case Study

Optimizing glucose concentration, as well as that of other carbon sources, is a common challenge in upstream bioprocesses for both the biopharmaceutical and industrial biotechnology sectors. Batch processes, while simple to design, do not afford the opportunity to control glucose throughout the course of the process. Manual fed-batch processes improve control but do not manage optimum concentrations of nutrient feedstocks during a bioreactor cycle. The real-time, in situ glucose-sensitive probe we describe measures glucose concentration continuously throughout the course of the bioreactor cycle. This information is used to directly control nutrient feed pumps so that an optimum can be achieved—a nutrient feed rate matched to the real-time metabolic requirements of the process.

Experimental Details. The Ranger System is used to control glucose additions to a Saccharomyces cerevisiae (a type of yeast) fermentation that produces alcohol. In a novel process described below, the S. cerevisiae fermentation was operated in fed-batch mode with glucose limited throughout the process and fed under control of the Ranger System.

This experiment compared three feeding protocols. In each case the fermentation received a total of 180 g/l of glucose but using three different feeding regimes. As the base (control) case to demonstrate the characteristics associated with an uncontrolled process, the first regime used a fixed, timed, pulse feed of 20 g/l every 4.5 hr. monitored by the Ranger Probe. The second regime involved an improved feeding strategy, providing a pulse feed of 20 g/l when the Ranger Probe detected a 20% drop in metabolic rate. Finally, the third regime used a pulse feed of 1 g/l at higher frequency based on the Ranger probe's detection of a 20% drop in metabolic rate. To confirm the Ranger system's operation, samples were also periodically extracted from the bioreactor for offline analysis of nutrient and product concentrations.

Monitoring Fed Batch. The graph in Figure 3 shows the real-time continuous Ranger signal and the corresponding data points from the offline nutrient analyzer. The fermentation is split into two distinct phases: During the first phase, from 0–15 hr., feed pulses are being added faster than required, leading to a long-term increase in glucose concentration; for the second phase, at around 15 hr. the yeast has achieved its maximum metabolic rate and from 15 hr. onward the feed pulses are being added more slowly than required, leading to a period of inactivity before the introduction of the next feed pulse. For the whole process there is a clear correlation between the measured glucose concentration and the Ranger signal.

Figure 3. A comparison of the glucose content as measured by an offline nutrient analyzer and the results provided by the Ranger System |

Controlling Fed-Batch Feeding. The ability of the Ranger System to indicate relative nutrient concentration in situ and in real-time makes it suited for use in intelligent feeding regimes, which automatically adapt to the metabolic requirements of the organism being used. To demonstrate the Ranger System's ability to control pulse feeding, the rate of change of the Ranger signal was used as a trigger to initiate feed pulses. As with the uncontrolled case, the feed pulses were a fixed dose, but the frequency of feeding was automatically determined by the Ranger System.

Figure 4 shows that the initial stage of the process, up until approximately 15 hr., is run as a batch process where the original glucose within the media is used by the yeast. Once the fermentation process begins depleting nutrient from the media to a point that reduces the rate of change in the Ranger signal, then a feeding pulse is triggered to boost nutrient concentration, with subsequent feed pulses being initiated in the same manner. The characteristic saw-tooth pattern seen in the Ranger signal shows the feed control loop, and is indicative of the varying glucose concentration within the media. As the fermentation progresses, the yeast's requirement for glucose lessens. In response, the frequency of the feed pulses is automatically reduced by the Ranger System. The longer-term upward trend in the Ranger signal is due to the accumulation of product (alcohol) within the media, which can be clearly seen from the offline nutrient analyzer data.

Figure 4. Ranger System readings in response to the feed control loop |

Figure 5 shows the fine control achievable with the Ranger System. By delivering only 1 g/l of glucose when detecting a 20% fall in metabolic rate, Ranger automates a pseudo-continuous feeding regime to optimize the yeast's metabolism, thus maximizing the rate of alcohol production.

Figure 5. The Ranger System can achieve fine control in fermentation applications |

Conclusion

We have demonstrated that the Ranger System can continuously and automatically control the feed rate of nutrients during the fermentation process. The resulting control loop shows a real-time indication of relative nutrient and product concentrations.

The Ranger System can be tailored to control nutrient addition for a variety of bioprocesses, both by optimizing the dose characteristics and the trigger point used to initiate feeding pulses. The real-time continuous nature of the Ranger System allows small and frequent feed pulses, resulting in automatic pseudo-continuous feeding that optimizes nutrient concentrations and product yields.

Real-time monitoring of key parameters of biopharmaceutical processes offers greater process control, leading to important cost savings and increased efficiencies. Achieving real-time monitoring requires the introduction of additional process analytical tools that are easy to integrate, economic to produce, and straightforward to operate. The ability to monitor glucose levels in real-time is a significant step forward in biopharmaceutical process control.

The Ranger System, Ranger Probe, and Ranger Manager are registered trademarks of Stratophase Ltd.

ABOUT THE AUTHOR

Bill Campbell is CEO of Stratophase Ltd., Romsey, U.K. He can be reached at +44 (0) 1794-511-266 or [email protected].