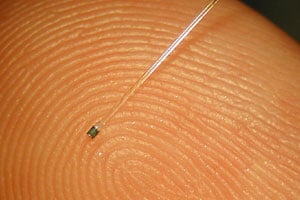

The Samba pressure transducer consists of a 0.36–0.42 mm o.d. silicon sensor chip attached to the tip of a 0.25 mm o.d. optical fiber (Figure 1).

Figure 1. A photo of the sensor resting on a fingertip to show scale |

Pediatric Care

Because pressure is such a common indicator of changes in physical condition, the sensor's small size, flexibility, and biocompatibility render it suitable for use in clinical or preclinical settings. The sensor can be inserted into extremely narrow passages, such as those in small blood vessels, the urethra, the gastrointestinal tract, and the endotracheal tubes in the lungs of newborns. While the sensor system has been used successfully to monitor pressure in adult patients, its small size has proven to be most useful in the care and treatment of small children.

Figure 2. The sensor's operating principle |

Preclinical Research

The system is also being used in preclinical research involving small animal models, to monitor the health and well-being of an animal. Imagine a system that can monitor pressures inside the tiny heart and cardiovascular systems of small mammals such as mice, for example. Inserting the sensor between vertebral discs or in particular muscles may allow us to learn more about how certain situations cause strain and damage. Similarly, we may be able to elucidate the origin of pain, and obtain an objective measurement of pain, as well as to supervise orthopedic rehabilitation and surgery. The miniaturized pressure transducer, capable of handling pressures up to 17 bars, is ideal for such applications. Insertion in the disc can be performed using a guiding needle, enabling both static and dynamic conditions to be investigated. This particular orthopedic use has been tested in pigs.

Figure 3. Sensor specifications |

Enhancing Advanced Imaging Techniques

Because neither the sensor chip nor its optical fiber contains metal components, the system does not interfere with, nor is it affected by, magnetic or RF fields. It is therefore compatible—where conventional electrical transducers are not—with several of the advanced imaging techniques used to visualize functional information about a specific organ or physiological system. The system is already being used, for example, with imaging techniques that use a pressure (blood or respiratory) signal to trigger the image acquisition. Such imaging techniques include Magnetic Resonance (MR) imaging, Positron Emission Tomography (PET), Computed Tomography (CT), and Single Photon Emission Computed Tomography (SPECT). Research is also underway to investigate the use of pressure measurements from our sensor systems to decrease artifacts in MR imaging, as well as to investigate the quick, tiny physiological changes taking place in various parts of the body in conjunction with trauma, surgery, and pharmaceutical therapies.

Figure 4. Control unit specifications |

Industrial Applications

Originally developed for use in the automotive industry, Samba technology is also applicable to a wide range of other industrial processes that require a flexible, robust, and small transducer to produce stable, accurate, and high-resolution measurement of pressure changes and gradients. The tiny size of the Samba Sensors' fiber-optic micro transducers allows them to be used in a variety of applications that involve encapsulated gases or liquids—especially those that must pass filters, compressors, and valves—in automotive, pulp and paper processing, and mining industries as well as oil or gas pumping facilities. In addition, the biocompatibility and non-toxicity of the sensors make them particularly useful for a variety of applications in the pharmaceutical and food and beverage industry, including processes that require pressure measurements to be made in electromagnetic magnetic fields or in conjunction with microwave techniques.

ABOUT THE AUTHOR

Henrik Mindedal, MSc, can be reached at Samba Sensors AB, Vastra Frolunda, Sweden; +46 31-704-91-60, [email protected], www.samba.se~